Getting Comfortable With the Brush Hog

Most people buying a tractor get some form of three point cutter with it for brush hogging. And yes, they are a little intimidated the first time they use it. Usually it is called a brush hog (or Bush Hog, but that’s a brand name). In the U.K. it’s a “topper.” It’s a “slasher” if you’re in Australia. But regardless of what it’s called, it’s a rough cut rotary cutter to clip pastures. Today we’ll discuss how to operate a brush hog. Then, I offer ten tips to make that first run across the field a pleasant experience.

Before we start, let’s make sure the tractor and cutter are field ready. On the brush hog: check the gearbox oil, grease it, level it and check the blade area to make sure nothing’s wrapped up around there. On the tractor: check the inflation of the back tires (so the cut is even). Make sure the radiator is clean and debris-free, because we’re going to give the tractor a little workout when cutting.

To brush hog, all you do is engage the PTO. It may be button or lever activated if fully independent. On certain tractors, however, you may have to push the clutch down and move a lever, then gradually let up on the clutch. You want to be between 1200 and 1600 RPM’s when turning the PTO on. Then all you do is drive!

Having said that, there are ten practices I’d recommend to make your first trip across the field uneventful. These can also apply if you’re an experienced operator.

Ten Tips For Easier and Safer Brush Hogging

1.If you have a quick attach bucket, take it off. Those things stick out and can hit posts, trees, etc. Drop it in the weeds and you don’t have to worry about it.

1.If you have a quick attach bucket, take it off. Those things stick out and can hit posts, trees, etc. Drop it in the weeds and you don’t have to worry about it.

2. Drive slow until you get comfortable. Low gear in hydro, low range on a gear-drive tractor. Take it easy until you get a feel for what you’re doing.

3. Watch for obstructions. That can include objects hidden in the weeds, but also watch where your roll bar goes. Low limbs or utility wires can encounter the ROPs structure and create an extremely dangerous situation.

4. Start in low grass if you can. I never like to engage the PTO where it starts out cutting. If you can kick in the PTO in an area you’ve already mowed and drive into the weeds. It’s easier on the tractor, cutter, and you.

5. Watch the tractor temperature gauge. When brush hogging mature weeds, the seeds can shatter and your fan may suck them right into the radiator. If the gauge is moving toward the red area, stop and clean the radiator out.

6. Get sun protection. You can cook yourself pretty quickly in the sun brush hogging for hours on end. I recommend the Rhinohide canopy (available here: https://asktractormike.com/products-for-sale/) because it’s really tough. And you can take it off when you go back into the woods to cut a trail.

6. Get sun protection. You can cook yourself pretty quickly in the sun brush hogging for hours on end. I recommend the Rhinohide canopy (available here: https://asktractormike.com/products-for-sale/) because it’s really tough. And you can take it off when you go back into the woods to cut a trail.

7. Keep people and pets away from where you’re brush hogging. Blades on a cutter run up to 18,000 feet per minute. When they encounter something in the field, they can throw it an amazing distance in all directions. Don’t let anyone around you when you’re running a rotary cutter!

8. Start mowing back and forth in the center of the field. Bush hogs generally stick out on both sides of the tractor. Until you get a feel for that, don’t try to move up next to trees and fences.

9. Avoid draws, or valleys. Going through a dip in the field can put your equipment in a bind and mess up a PTO shaft (if you’re lucky). It could also damage the cutter gear box or the tractor PTO housing. Those are all expensive fixes that you don’t need.

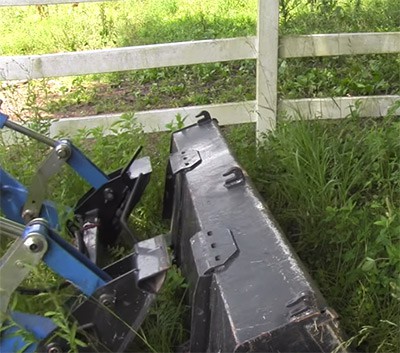

10. Finally, watch your butt or the back of your cutter. When turning, the rear of the brush hog will swing around really fast. That means you have to be real careful it doesn’t contact anything. It sticks out more than you think it does when you’re a new operator.

10. Finally, watch your butt or the back of your cutter. When turning, the rear of the brush hog will swing around really fast. That means you have to be real careful it doesn’t contact anything. It sticks out more than you think it does when you’re a new operator.

It’s tremendously satisfying to look back and see the newly-groomed field when you’re done brush hogging. Do it a few times, get comfortable with the equipment and the process, and it will be a less daunting task.

I can think of an exception to #1, and that’s when you’re dealing with really tall weeds or grass, in a field that hasn’t been cut for a long time. Our cropland sat fallow for 3 years up until recently, since we were transitioning from conventional farming to organic and the law requires it. The last farmer we had planted horseweed as a cover crop; it grew to be 6-7 feet tall. When it came time to bush hog the fields in preparation for planting corn this past spring, I left the loader bucket on the front of the tractor and ran with it down low, 8-10″ off the ground. That way if there was anything lurking in the weeds that might damage the tractor, the bucket would hit it before the tractor did, and I’d know to stop and deal with the obstruction. That horseweed was not only tall, it was really thick, and it was hard to see what was coming up until you got right on top of it. So I mowed slowly and kept the bucket down low and out front, to be on the safe side.

I agree unless in tight quarters

SO HAPPY TO HAVE YOU BACK, I WATCH YOUR VIDEOS ALL THE TIME & LOVE THEM ALL !

Great advice, Mike!

I’ve had a Deere brush hog for about five years and have never used it. It came with my used tractor as a package deal.

Took it into my dealer last year to have it checked out (slip clutch, sharpened,etc) and am anxious to use it on some acreage I acquired (timber and meadow) that has never been mowed before. Lots of wild blackberry canes that are taking over part of the meadow.

My neighbors horses have been in there for years and, needless to say, the ground is full of depressions due to them being in there in the wet winter months. Also, lots of mole activity.

I’m sure the ride will be bumpy!

Will let you know how it turns out.

Tractor Mike,

I love you! You have saved my behind here on the ranch. My husband died unexpectedly 4 years ago. Although I had used the tractor to put out round bales, he would never teach me how to use the brush hog. When I HAD to I was petrified. My son came out to show me how and I was in tears I was so scared but I told him to ignor and just show me. It was so scary. I spent a big part of that first summer mowing very slowly my 58 acres of pastures. I only got half of them done. The next year I faced the music when wild blackberries threatened to take over. Today I’m pretty good at it and it doesn’t take me near as long. I can even hook it up thanks to you!

You can’t even imagine how much your videos help me.

Thank you!

Please keep doing this forever!

Kathe Wells

26836 NCR 3253

Wynnewood, OK 73098

I believe that an important tip would urge operators to check their manuals for the proper PTO RPM when cutting. Also take some time to figure out the proper deck height and then set the gauge so you can repeat it every mow session.

I agree with the tips . . . I am a new tractor owner and brush hogging is a concern for me. Mike has been a blessing!!!

I put in about 4 hrs brush hogging in N Florida a couple of days ago and that Rhino Shield top made a huge difference! Glad to report that working this attachment between the pines is becoming almost second nature but still need to be aware of the tips you listed

Why did they stop using the spin out adjustable rear wheels on new tractors?They are handy.

Yeah they are. My guess for the reason they’re not offered anymore is simply because they’re expensive. They make it easy to adjust your tread width and add a bunch of weight to the back of the tractor which is good for stability. I’d bet that there are a lot of people, including younger farm people who have never seen them.

My brother is considering purchasing a house that has a good amount of overgrown sections of grass that he wouldn’t be able to cut with a regular mower. It was helpful when you explained that it is important to avoid dips with a bush hog because the cutting mechanism can get damaged. If my brother does end up purchasing this property, it would probably be best if he had a professional company cut the property.

thanks for sharing information tractor and implements I am just forward friend and other people.

I’m thankful your article mentions the importance of taking things slow with a slasher. I’ll be sure to send your article to my older brother. He is looking to cut the grass on his ranch.

My Father insists on driving his tractor (with bush hog attachment) in reverse to mow his field. His reasoning being to protect his radiator from the tall grass. What is your opinion of this practice?

The only things I see wrong with it are 1) visibility and knowing what you’re getting ready to run over 2) a sore neck and 3) laughing neighbors. I’ve learned with dads, once they make their mind up it’s tough to get them to change. If it makes him happy to mow in reverse I’d let him. I may cover this in a future video…

I just read that he could brush hog with the bucket down close to the ground which would protect his radiator. provide his bucket is on. I used this technique this afternoon and seemed to work great, also protection from what can be unseen in front of you.

Bush hog question

Husband on a new Kubota with 4ft bush hog.. we have a quick hitch..he put it in.. side swiped a small tree 1-2” in diameter.. now he has a vibration in the steering wheel.. help..

Deb, a tree 1-2″ in diameter is not going to damage the steering of a small tractor. I’m not sure what is going on, but first, make sure the vibration is not coming from a blade stuck underneath the pan on the bush hog. Watch this: https://youtu.be/UIe2lOc5H5w. Make sure anytime you’re under that bush hog that it’s supported by jack stands and the tractor is off and the brake locked! Also, make sure the bush hog didn’t come out of the quick hitch and that’s making the steering jerk. I don’t think the problem is the steering, is something else that you’re feeling in the steering wheel. Hang in there, it takes more than that to tear up a tractor!

I truly appreciate that you are spreading awareness through your blogs to the people.

I had an occasion to tear up the rear seal on my 211 yanmar while bush cutting. the grass was fairly high and i did not think of it wrapping around the drive shaft. I was fortunate that the repair shop went right to the problem and solved the hydraulic leak. from now on, i’ll back slowly into the high grass instead. Just a thought someone might learn from. i’m a city boy learning how to live in the country and this is just another lesson learned

What gear should I run my JD 2040 manual transmission in to operate the Woods M5 Brush Hog. And at what RPM?

Rated engine speed on that tractor is 2500 RPM, that’s where you get all of the horsepower that the engine produces. So, wrap it up to 2500 and find a gear that you’re comfortable with and you’ll be good. You’ll probably be in medium range 2 or 3, is my guess. Now, you don’t have to always run at 2500 RPM, if you’re doing something that doesn’t require all of the tractor’s horsepower you can go below, brush hogging in the spring usually takes a lot of horsepower, you can throttle down when just clipping seed heads in August. Good luck!

-Mike

Thanks for all the great information! Last week was my first time using a bush hog I too was a little nervous. I’m a grandma so I appreciate everyone’s tips.

Thanks

What is the best way to travel from place to place on the farm while the brush hog attached? wheel touching the ground or elevated?

Thanks..

T.C.

Either is fine, but you don’t want it just off the ground where it’s bouncing up in the air and hitting the ground hard sporadically. If it’s on the ground, that works fine, if it’s up in the air not touching anything, that’s fine, anything in between where it’s pounding on the ground as you hit dips in the field is bad. I prefer to have mine up high enough that it never touches the ground.

-Mike

My dealer on a new Bushhog 116 told me to start the pto in low throttle and when it’s engaged to pick it up to full speed. Does this sound right? How do you do it?

That is the same instructions for my Kubota and Land Pride brush hog. Also, manual states to lower the engine RPM before disengaging the PTO.

Mike,

Are you aware of or have an opinion about converting a four wheeled bush hog (Scorpion) to a single mid rear wheel? The bush hogs front wheels sometimes contact the my tractors rear tires

What can I do to create more space between the rear tractor tires and the bush hogs front wheels?

Such an amazing post, very informative and I will definitely suggest other people about it for sure.

https://www.tractorjunction.com/mahindra-tractor/

Great post man, keep up the nice work, just shared this with my friends

Finding very informative and lovely content. Thanks for sharing this.

[…] To brush hog, all you do is engage the PTO. It may be button or lever activated if fully independent. On certain tractors, however, you may have to push the clutch down and move a lever, then gradually let up on the clutch. You want to be between 1200 and 1600 RPM's when turning the PTO on. via […]

Mike I have a7 ft.land Pride ,and a Intnational 674/ 4 cyl diesel.I find the bush hog leaves a uncut strip in the middle of the swath.The Hay is 3/4 ft. Tall at times.I have two new blade installed- no difference, had the PTO clutch kit installed and RPM indicator to check to see if ok539 was the reading.I thought the hay was not clearing properly so have removed the metal plate off the back to try that But had no chance to try as yet. The rotation is equal all around so no bent shaft on gear box??no vibration what ever.

Jim,

Sorry for the slow response, I don’t check messages here much. I’m not sure why you’d have that issue. How wide is the uncut strip? You might reply to mi**@************ke.com and I’ll get back with you faster.

-Mike

Glad you liked the ideas!

Thanks for this useful content. It’s always a pleasure to read your great posts filled with tips really!

Very informative content, thank you sharing information.

We got to learn a lot of new things from your post. Thank you. The website is amazing. It is nice to visit the site.

Truck Price

Nice blog thanks for sharing it content is easy to understand